Treating Wood With Oil - The Ultimate Guide

Applying wood oil is a great way to enhance the look of both interior & exterior timber, as well as providing it with added protection. Like all decorating however, it is crucial to do it properly if you want the best results. In this guide we are going to cover the different types of wood oil, which wood oils are the best and how you go about applying them.

What Is Wood Oil?

Being a natural material, wood is treating differently to other building materials that we find around the home, such as concrete, metal or plaster. The high porosity of wood and its natural beauty allow it to be finished and treated in a range of ways. There are four main types of wood treatment that you will find:

- Wood paint - these products offer a solid, opaque coloured finish that completely covers the grain of the wood. These come in satin, eggshell, gloss & matt finishes that all vary in their level of sheen.

- Woodstain - these offer a coloured finish while enhancing the grain of the wood by penetrating into the surface.

- Wood varnish - these create a protective barrier on the surface of the wood that does not alter the colour of wood but will seal and protect it.

- Wood oil - these penetrate into the surface of the wood to nourish it and enhance it's natural beauty, creating an easy to maintain protection that becomes part of the wood rather than creating a coating on the timber.

Oil is one of the most popular ways to finish wood thanks to its ability to replenishing the natural oils that you find in the wood, plus it provides added oils to improve its performance.

Wood oil can be used on both interior & exterior wood in the form of furniture, decking and floors, to name a few.

Why Apply Oil Wood?

As we have mentioned, wood oil provides benefits both to the appearance and performance of wood. By penetrating in the timber, wood oil acts much in the same way as moisturisers do, helping to provide added oils that are lost over time. When left to age and when exposed to wear and tear, wood can lose oils that are crucial to it preventing damage. Wood oil is crucial for protecting timber, both internally & externally.

Here are a number of reasons why it is important to apply oil to wooden surfaces:

- Weathering - when left exposed to the elements, wood can very quickly become weathered & damaged due to the high porosity of the material. Untreated timber has little resistance to water absorption, which can lead to the wood rotting and decaying over-time.

- UV degradation - UV rays can cause wood to grey, discolour & lose flexibility, which can be prevented by nourishing the wood using oil.

- Fungal growth - exterior wood a natural, mineral surface when saturated with water creates the perfect surface for fungal growth such as lichens & algae to grow, leading to large green patches on the timber. Applying wood oil can help limit this fungal growth.

- Wear & tear - whether internal or external, wood can become scratched and damaged over time, especially when it is used on kitchen worktops. Oil can help protect the wood from this wear & tear, helping to keep it looking beautiful for years to come.

Types of Wood Oil

Wood oil like all decorative finishes comes in a range of forms to suit different requirements. The different forms of wood oil vary in terms of:

Surface

The surface you are oiling has a huge impact on which oil is most suitable. Timber surfaces are found in a wide variety of places around the home, from floors to furniture. Each surface has a different requirement, meaning they must have an oil specifically developed with that in mind. Decking oils for example are designed to offer a durable weatherproof coating that contains a non-slip additive to prevent slips when dry. You can find a wood oil for decking, indoor wooden flooring, furniture, doors & kitchens worktops, to name a few.

Finish

Decorative coatings come in a range of finishes that vary in terms of level of sheen. The more sheen a finish has, the more light in reflects. These finishes include, matt, eggshell, satin and gloss, with matt having the lowest level of sheen and gloss having the most level of sheen. The most common forms of finish you will find it a wood oil is a matt & a satin finish, which allows you to achieve the two most popular looks for natural wood.

Type of wood

Contrary to popular belief, the type of wood you are treating will have an impact on what oil is suitable to use. Many wood oils will stipulate which types of wood it is suitable for. Whether you are oiling oak, pine, spruce or beech, to name a few, check the oil you are using first!

Colours

Some oils can offer a different coloured finish once applied, which must be considered. Transparent finishes are colour shades which allow the wood’s natural grain and other characteristics to remain visible, while clear finishes do not contain any colour pigments, meaning they simply provide an enhanced colour.

The Best Wood Oils

The type of wood oil that is best for you depends on a number of things, including the type of wood, the surface you are oiling & the overall look you want to achieve. It is not a one size fits all when it comes to wood oil.

Whatever wood oil you decide to opt for, we recommend that you go for one that is good-quality, as although it can be tempting to go for a cheaper option, the level of protection & performance you will get is reflected in the price you pay. Wood is a complicated surface that requires a quality oil that will provide it with everything it needs to look beautiful & stay protected over the course of a number of years.

The Best Interior Wood Oil

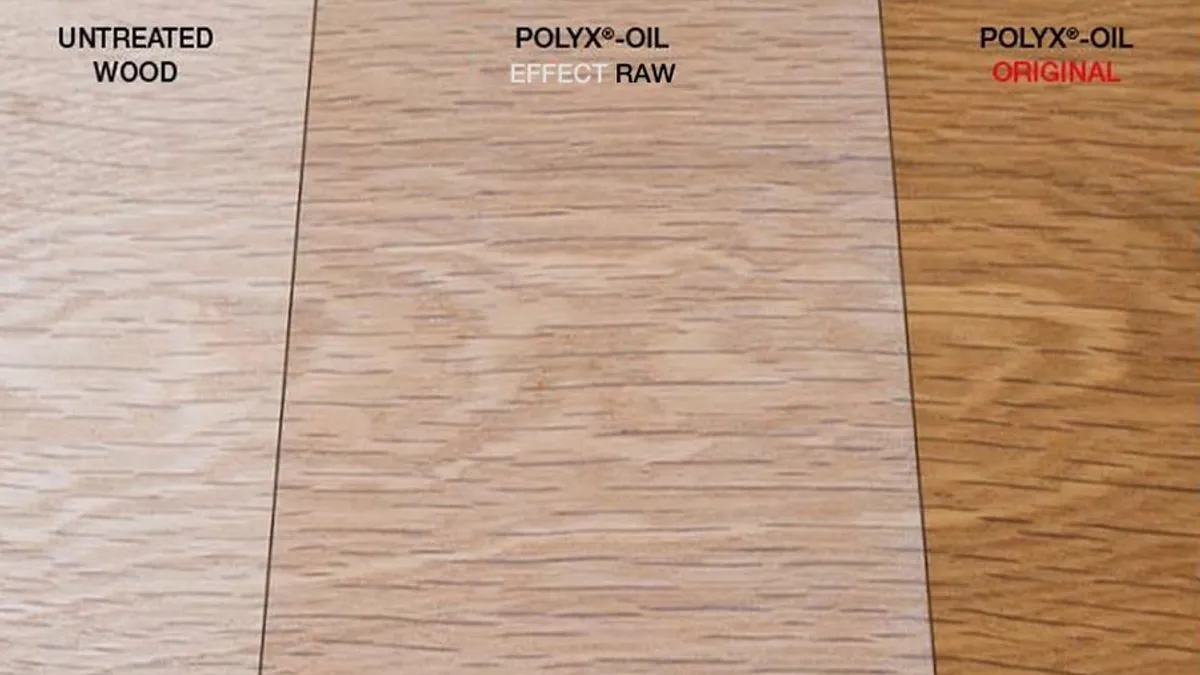

When it comes to applying a wood oil to interior wooden floors and furniture, we highly recommend Osmo Polyx-Oil Original. This is a wood oil that is highly durable, water and dirt resistant , microporous, allowing it to naturally breathe to prevent cracking, peeling or flaking.

Osmo Polyx-Oil is incredibly easy to use as it does not require any sanding for spot repairs or future applications, meaning it is easy to maintain long-term. It is available in clear satin & matt finishes, plus white with Osmo Polyx-Oil Tints.

As with the rest of the Osmo range, Osmo Polyx-Oil is developed to the highest possible standards, from the coverage to the durability. While it may seem the all wood oils are doing the same job, this couldn't be further from the truth. Overall, for interior wooden floors and furniture, it provides everything you need in a wood oil!

Key Features:

- Highly durable and hardwearing

- Water and dirt resistant

- Enhances the wood’s natural character

- Resistant to common liquid spillages such as water, juice, tea, cola and wine

- Saliva-resistant and sweatproof, suitable for children’s toys

- Microporous/breathable finish

- Spot repairs can be made without sanding

Top Tips:

- Clear oils can darken the appearance of the wood

- The surface can take 2-3 weeks to fully cure

- Apply a base coat of Osmo Wood Protector when using in moist environment rooms such as bathrooms or kitchens

- Suitable for Oak, Pine, Spruce, Beech, Ash, Alder, Douglas Fir, Birch & Larch

The Best Wood Oil For Decking

When it comes to the best decking oil we recommend Clear Decking Oil from Sadolin. This penetrates deep into the decking to provide great weather protection and water repellency, which helps the decking remains slip free. It also contains colour protective UV filters, which help to prevent UV degradation and thanks to the weather protection, the wood oil also resists mould and algal growth, keeping decking looking pristine.

Sadolin Clear Decking Oil does not alter the colour of the wood, but can appear matt or satin in finish, depending on how much product is applied and the density of the timber.

Overall, it contains everything you can ask for in a decking oil at a great price, which is why we highly recommend it.

Key Features:

- Highly durable finish for decking

- Replaces natural oils lost through weathering

- Contains colour protective UV filters

- Resists mould and algal growth

Top Tips:

- Leave 16 hours between coats

- Planed hard and softwood has a coverage of up to 8m² per litre, while sawn softwood has a coverage up to 15m² per litre

The Best Wood Oil For Kitchen Worktops

Osmo Top Oil is a tough and durable, hardwax-oil finish that has been specially designed for use on interior kitchen wooden worktops, tables and other wooden surfaces. The wood oil is not only water repellent, durable & microporous, like other Osmo treatments in our guide, but crucially it is food safe (EN 1186), making it suitable for use on a range of kitchen surfaces.

It is also resistant to common liquid spillages such as water, juice, tea and wine, helping to keep kitchen worktops looking clean & pristine without marking.

Available in satin & matt finishes, plus a natural finish that has white pigments, offering a light, natural finish to the wood.

Key Features:

- Spillages will tightly bead on the surface without leaving any marks, simply clean by wiping with a cloth

- Food safe (EN 1186)

- Safe for use on children’s toys (EN 71.3)

- Extremely water repellent

- Very durable and hardwearing

Top Tips:

- Suitable for Oak, Pine, Spruce, Beech, Ash, Alder, Douglas Fir, Birch & Larch

- Has a 2-3 week curing time

The Best Wood Oil For Doors

Again, from Osmo, Door Oil is a specially designed wood oil for bare softwood & hardwood interior doors, offering a highly durable, protective finish. The solvent-based formulation will not crack, peel or flake, while enhancing the natural beauty of the wood.

Osmo Door Oil comes in two forms; raw matt and clear satin. Raw matt (3033) preserves the wood’s light colour (lightly white pigmented), while clear satin (3060) enhances the wood’s natural character, giving you flexibility to achieve the finish you desire.

Osmo Door Oil has become hugely popular in recent years, and is even recommended by many door manufacturers to finish their timber doors.

Key Features:

- Suitable for solid wood doors, selected veneered doors and furniture

- Extremely water and dirt resistant

- Saliva-resistant and sweatproof, also suitable for children’s toys

- No sanding necessary for future applications

Top Tips:

- Recommended use on interior wooden doors, frames and joinery

- Osmo Wood Protector is recommended as a base coat for doors and joinery in wet-rooms such as bathrooms or small kitchens to increase the water resistance.

How To Apply Wood Oil

The application of wood oil can vary hugely, depending on the surface & the oil you are using. Wood is often either overprepared before application or underprepared, leaving it in a less than optimal condition to apply oil. While the application process can vary, here are a number of tips for how to best apply wood oil.

1. Test

Not all wood is the same, so you can never guarantee that the same oil will look the same when applied to different wood. Wood oils can have different effects on various types of wood so we strongly recommend conducting a small test on an inconspicuous area of wood before you start oiling the full surface. This will allow you to get a better idea of what look the oil will leave.

2. Wood condition

The wood must be clean & dry to apply oil. When oiling exterior wood, ensure it is frost-free with a maximum moisture content of 20%.

3. Preparation

Clean or slightly sand old microporous oil-based finishes before you apply any wood oils. Start sanding the wood with a coarse grade of sandpaper, followed by a finer grade before application. P100-120 grit sandpaper is recommended by Osmo for ingredient-rich hardwood species, P120 for most wood species and finally P150 for softwood species, prior to brush application.

3. Filling

You can fill wood before oiling by using a wood filler. We recommend trying to match the existing wood's colour to the filler in order to achieve a uniform finish. On large areas, you can mix a wood putty with sanding dust to match the filler to the wood’s natural colour.

4. Basecoats

Osmo recommend applying Osmo Wood Protector for interior wood prone to moisture, usually in bathrooms or kitchens. This can help protect the wood once the oil is applied.

5. Over application

Over application of oil can leave an undesirable finish and can also increase the drying times. With high-quality oils, such as the Osmo range, they can go a long-way thanks to their coverage. Osmo themselves state that you must apply their products thinly, as that is the secret to achieving the best results.

Make sure when applying wood oil you brush out as far as possible with the oil you have. Wondering how to know when you need more oil on your brush? You can often feel wood oil dragging or feeling sticky when you need to get more oil on your brush. If the brush isn't dragging, keep spreading it over the wood. You can wipe excess oil off the wood using a clean cloth.

6. Using the right tools

Using high quality decorating tools & supplies is wise if you want to achieve the best results easily & effectively. For example, Osmo have developed their floor brush which makes short work of large floored areas with high coverage capacities to the ability to produce professional looking results every time.

There are five ways to apply wood oil; brush, roller, cloth, spray & buffing.

Brush

If using a brush, apply a thin, even coating of oil along the wood grain with a high quality brush and spread well. Remove any surplus or excess with a dry cloth. When using a brush usually 1-2 thin coats are required. Use the Osmo Floor Brush for larger, open areas.

Roller

The same process applies to using a roller, with a short-pile microfibre roller being the best option. This is a great option for all surfaces, including floors.

Cloth

When applying wood oil with a cloth, ensure you use a dry, lint-free cloth and apply the oil thinly, thoroughly and evenly along wood grain. You can then remove any excess with a dry cloth. It will often take 3-4 thin coats of oil when using a cloth.

Spray

You can spray wood oil, with a1.2-1.5mm spray gun nozzle at 1.8-2.5 bar. This is only recommended for spray professionals.

Buffing

Lastly, you can also apply oils by buffing, by spreading the finish evenly with a brush or roller, waiting approximately 30-60 minutes and then buffing the surface using a pad.

7. Sanding Between Coats

Sanding is not necessary between coats, although de-nibbing the wood with a pad can help to remove any imperfections from the surface of the wood between coats.

8. Curing

As with many decorative finishes, wood oil has a curing time until it is performing to its maximum potential. Before the oil is cured, it can be susceptible to damage, so it is crucial to wait until the curing time is over in order to put the wood under normal wear & tear. Newly oiled wooden surfaces require approximately 2-3 weeks to completely cure and harden properly before normal usage, but check with the manufacturer of your chosen wood oil before applying.

With floor oil, we do not recommend covering the surface with rugs or carpets until fully cured.

9. Maintenance

Depleted wooden surfaces that have been oiled will no longer repel water & can sometimes need reapplying. Avoid dragging hard and heavy objects across the surface to prevent the wood from being scratched.

When renovating or recoating an already oiled surface, one coat applied to the clean and dry surface is usually sufficient. You do not need to sand this surface.

10. Cleaning

Wood, much like our skin, needs to be cleaned using non-harmful cleaning products. Strong detergents and cleaning products will strip the natural oils and waxes away from the wood, so it is crucial to clean surfaces properly. Osmo for this reason developed their cleaning products that are highly effective at cleaning grime, while also maintaining protected surfaces and moisturising wood to maintain freshness.

They offer both their Osmo Wash and Care & Osmo Anti-Bac Wood Cleaner Spray which are both suitable for cleaning oiled wood without damaging the surface.

We hope this has answered any questions you may have had regarding treating wood with oil. At Painters World we have a wide range of trade paint, decorating tools & supplies available, so no matter the job, we've got everything you need! Shop our huge range of products today & get FREE next working day delivery on all orders over £50.